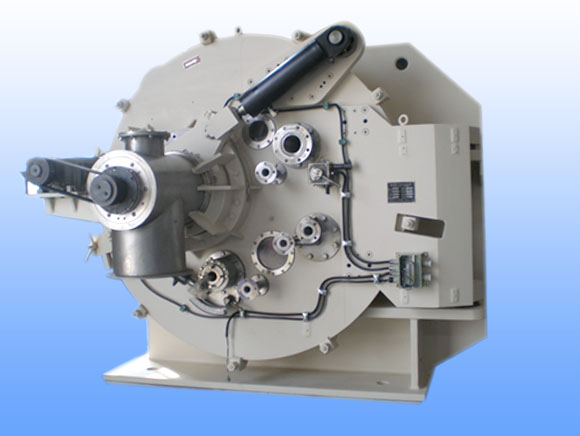

Siphon scraper centrifuge

Siphon scraper centrifuge

This machine is widely used in organic and inorganic materials, solid particle size in 0.05 ~ 1mm of chemical products, starch products, food, petroleum industry.

1. Application field

Chemical industry, such as lead powder, polyvinyl chloride, naphthalene, anthracene, polystyrene, polypropylene, ABS resin, resin, bisphenol, sodium pentachlorophenol, sodium chloride, ferric sulfate, caustic soda, urea, ammonium sulfide, ammonium chloride, sodium perborate, modified starch, bleach powder essence, trichloroethylhydrouric acid and so on.

Food industry, such as sugar dense, starch, salt, methyl tripionate, etc.

Fine chemical and pharmaceutical industries, such as sodium bicarbonate, herbicide, stearate, sulfonic acid, fumaric acid, niacin, antibiotics, salicylic acid, vitamin C sodium, etc.

2. How it works

The suspension passes through the feed valve into the high speed rotating drum, and the feeding process is controlled by a time relay or a feed controller until the drum is allowed to be filled to the maximum. During the feeding process, the solid-liquid separation has begun simultaneously and the penetration of the filter cake layer has been completed. The washing liquid is controlled by time relay or flow valve, and the washing liquid is sprayed onto the filter cake through the washing pipe and the jet hole, and the filter cake is washed. After the filter cake layer is dried, the lifting scraper or rotary scraper will cut the filter cake layer and send it out of the machine through inclined bucket or screw conveyor. These processes can be performed in manual or automatic control modes.

3. Main features

The machine has high separation factor, large siphon driving force and strong filtration ability

Good backwashing effect, strong regeneration ability of press cloth and residual filter cake layer

Large processing capacity, good separation and washing effect, widely applicable than the same type of scraper centrifuge

Adopting skimming pipe can improve the separation effect of difficult to separate materials

The use of screw conveyor discharging, discharging material more stable, no impact

It can be set to automatic or manual mode for cyclic operation

The parts in contact with the material can be made of corrosion resistant materials

The vibration absorber and the vibration absorber are required

According to different materials and use occasions, can be configured separately

4. Main specifications and parameters of the product

model | Drum diameter | The length of the drum | Drum speed | The separation factors | The drum capacity | Rotating drum loading quantity | The motor power | Overall dimensions | Machine weight |

GKH1250-N | 1250 | 630 | 1200 | 1006 | 372 | 455 | 75 | 2260*1840*1810 | 6800 |

GKH1600-N | 1600 | 1000 | 950 | 808 | 830 | 1000 | 132 | 4050*2250*2300 | 16500 |